CmController

A Measureing System optimised for the special requirements of SMT production.

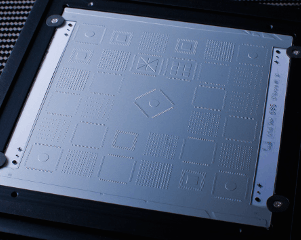

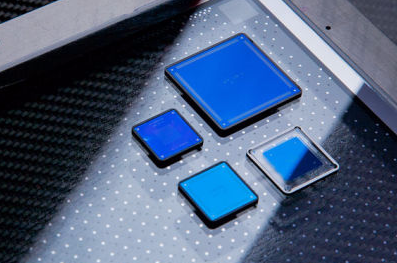

The CmController is a universal measuring system for the investigation of machine capabilities, tailored to the special features of SMT systems. Its use enables the analysis and optimization of the accuracy behavior of the manufacturing process and the early identification of error causes. The results obtained in this way facilitate the planning of new products, the introduction of new technologies and help with investment decisions. Furthermore, the verification of machine capability is an important part of audits.

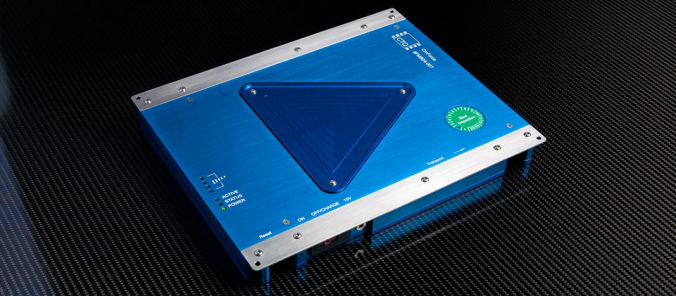

CmForce

Measurment and Analysis of Placement Force.

CeTaQ GmbH has developed a measuring system for the determination of placement forces under real process conditions. This makes it possible to detect weak points at an early stage and prevent component damage during assembly. With only one measurement, the force and energy input of each individual nozzle cell is known. This enables maintenance, repair or optimization measures to be carried out in a targeted manner if necessary.

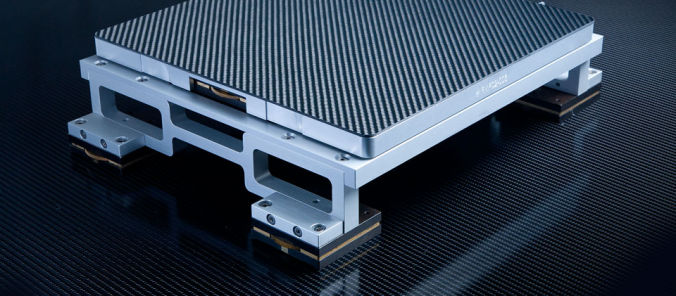

CmPrint

Measurement of the force-time curve during printing.

The first process step in the production of electronic printed circuit boards (PCBs) is printing. Solder paste is printed on the printed circuit board by means of a stencil. The quality of the paste print has a decisive influence on the overall quality of the finished printed circuit board. An important influencing factor is the accuracy and reproducibility of the squeegee force.